Annual product reviews confirm the regularity of present producing procedures. In addition, it will help in analyzing product quality and approach defects.

To start with time listed here? Enroll in a no cost account: Touch upon posts and acquire use of a lot of additional content.

The sponsor really should ensure that the paperwork shown in chapter 8, 'essential documents for the perform of a medical demo' of the guideline for good scientific observe are managed and available to those functions authorised to review them.

The recognize to applicants involves the submission of the declaration signed with the skilled person (QP) which the Energetic substance used is created in accordance with GMP.

Qualification status of areas, machines and systems as well as their influence on production course of action validation and analytical approaches

The info recorded in the traceability procedure must allow for productive investigation in case an incident occurs and will allow recollects of (possibly) defective products.

The sponsor has the final word accountability for all trial activities executed in the investigator internet site, but should find the recommendation with the QP of your IMP company, if at all possible, or even the clinical-trials pharmacist for the investigator web-site about:

It has to be identified, that these features needs to be reviewed While using the respective supervisory authority.

Storage disorders during transportation should be validated or monitored using a suitable temperature-measuring device that is effective at demonstrating fluctuations in temperature e.

Inside the absence of specific countrywide legislation or guidance, the outer packaging ought to have only one batch range, as allocated by the parallel trader. This batch range allocated because of the check here parallel trader must include two factors; (one) the batch number of the original pack and (2) a novel code identifying the repackaging/relabelling operate. The code to the repackaging run may possibly comprise numbers or letters or a mix of both of those.

The main target of the requirement is on former PQRs as well as the state and effectiveness of related steps:

The EU product quality review (PQR) needs a increased variety of items and locations for review compared with possibly the US product annual review (PAR) or Q7A PQR, and expands the review to incorporate quality devices and registration commitments.

When the answers are "no" to all 3 areas of this problem, Uncooked-product trending should not be integrated as Section of the PAR for the reason that any result from this trending would not be related for the aims with the PAR and wouldn't make any observe-up motion for applying alterations. To stop confusion, this instance is to not recommend that raw-material trending isn't required, but that it here should be executed as Element of A further application (e.g., seller qualification software) rather than the PAR software. It ought to be famous which the EU PQR requires the evaluation of your appropriateness on the raw-substance specs.

pharmaceutical makers of products that contains contaminated glycerol or propylene glycol did not complete whole id screening or assessments to find out DEG/EG about the contaminated raw materials.

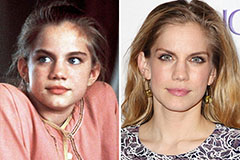

Anna Chlumsky Then & Now!

Anna Chlumsky Then & Now! Judd Nelson Then & Now!

Judd Nelson Then & Now! Burke Ramsey Then & Now!

Burke Ramsey Then & Now! Samantha Fox Then & Now!

Samantha Fox Then & Now! Nadia Bjorlin Then & Now!

Nadia Bjorlin Then & Now!